Structural Testing

RAETECH uses structural testing to refine and validate computer models. Once confidence in the virtual prototype is established design modifications can be explored in software reducing the number of physical prototypes that need to be fabricated and tested. This process improves the quality of component designs while shortening the development cycle.

RAETECH is equipped to test virtually any automotive component, structure or system. Examples are:

- Chassis torsion and bending stiffness

- Sway bar component and system stiffness

- Suspension component stiffness and strength

- Engine spin testing

RAETECH can configure structural tests at both the component or system levels. Testing sub-systems can capture the interaction between components which may be key to understanding the system performance. Joint and bearing interface compliances are often critical to the total system response.

Empirical models of joint compliances may be crucial to include in math models to accurately predict overall behavior. These math models are constructed based on physically measured data.

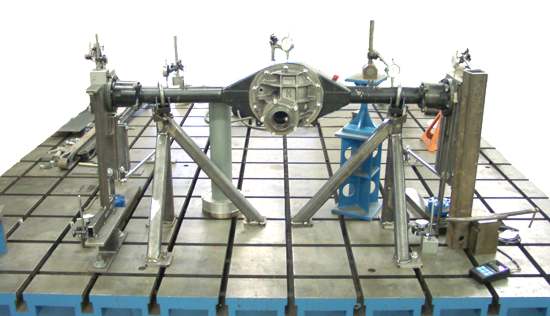

The rear axle assembly shown above, which includes the wheel bearing and hubs, is being evaluated for deflections due to corning and banking loads. The measured bearing compliances can be merged into full vehicle FEA models to properly simulate system responses.

For more Information about Testing Services Please Contact:

RAETECH Corporation

4750 Venture Dr. Suite 100, Ann Arbor, MI 48108

Tel: 734-665-2215

E-mail: